Search

Search

Search

Search

March 09, 2022

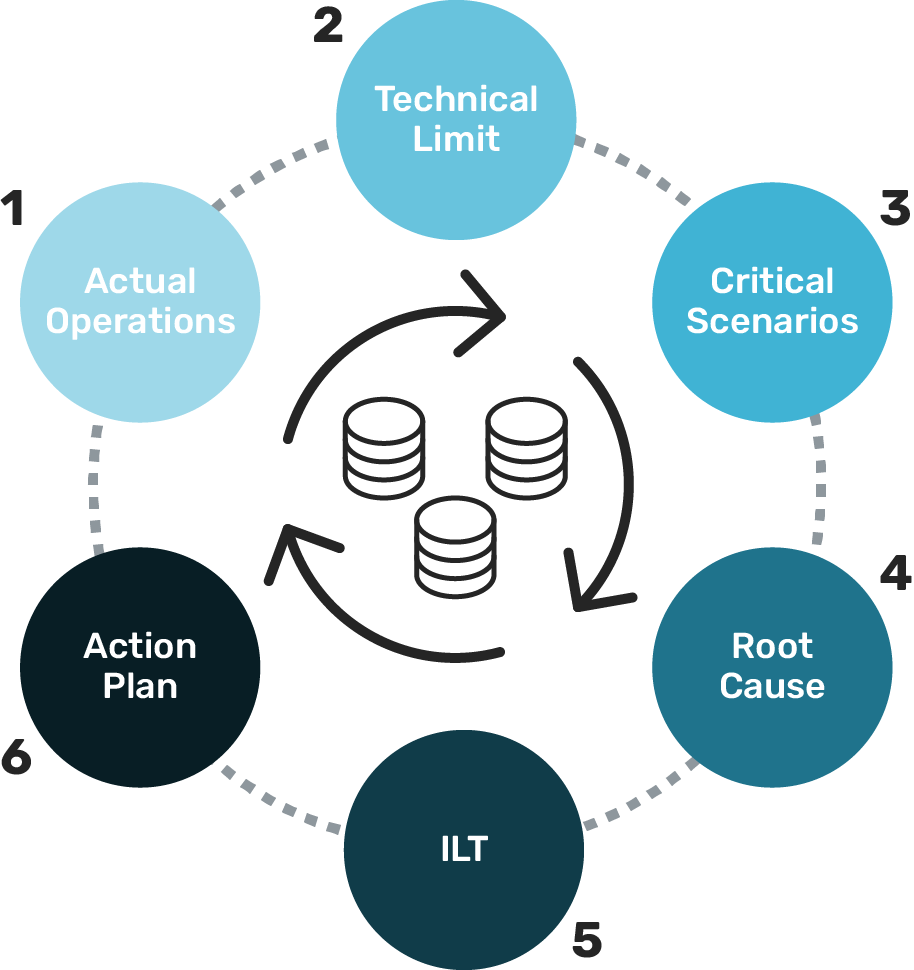

During the well construction process, every activity is carefully described and recorded by the onboard crew. This produces a massive amount of textual data in daily rig reports. Later, these records are used to detect specific events and calculate the duration of each operation inside the well to compare with performance metrics. Invisible Lost Time (ILT) is the difference between the actual operation duration and a best practice target (or a technical limit) to understand if a well is performing better or worse from correlated scenarios.

To perform ILT analysis, all manual descriptions must be checked by an SME who can correctly identify the type of ongoing operation. However, manual classification consumes a lot of time and may be done by multiple stakeholders. This may lead to inconsistencies caused by their subjective interpretations. To help overcome this problem, we have developed an Artificial Intelligence (AI) solution based on Natural Language Processing (NLP). The solution consolidates multiple data sources and then processes all necessary data to help quantify the impact of ILT.

An intuitive framework that leverages NLP and advanced analytics helps integrate several sources of drilling data within this robust solution to access, analyze, and visualize the combined data on the business analytics dashboard. With clustering analysis using machine learning, users can quantify the impact of ILT in the operation and understand scenarios that cause high Non-Productive time (NPT). This helps define better strategies for rigs and equipment usage in order to reduce the total well production time and enhance the performance of operations.

As a case study, there is a data analytics-based approach for the investigation of ILT in textual reports. This approach uses NLP and Clustering Techniques to create integrated workflows for data-driven decision making.

The proposed solution has the objective to automate the analysis of text descriptions in daily rig reports and identify operations where actual time is higher than the expected target without a clear reason of impact (i.e., well anomalies, rig maintenance, NPT, etc.). A well clustering engine is also available that helps define the technical time limit of the operations, based on unsupervised learning of well configuration and petrophysical characteristics of the well. A dashboard is provided to users to interact with the data, create custom analysis and identify ILT based on insights from historical performance of selected wells.

Visualizing data using intelligent dashboards makes it possible to reduce the time taken for analyzing historical well and rig data from days to minutes. With ready-to-use information, engineers and managers can take informed decisions to reduce ILT during E&P operations while also quantifying the potential savings.